Subscribe to our newsletter

Be the First to Know! Sign Up for New Product Alerts, Sales Promotions and Events!!

Your Bag making Source

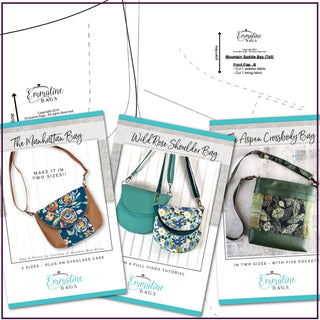

Browse our large selection of metal handbag hardware, sewing patterns, bag-related sewing notions, interfacing, fabric, & zippers specifically chosen to help today's bag maker. Find helpful, free sewing tutorials with full colour photos that will teach you to sew zipper pockets, slip pockets, bag straps, and more on our blog.

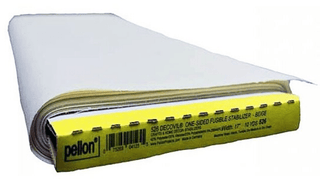

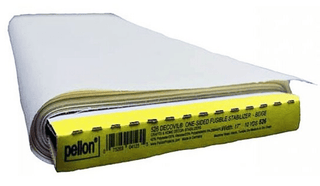

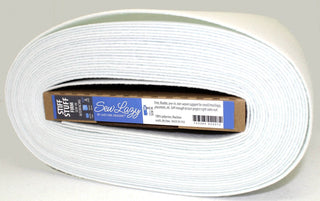

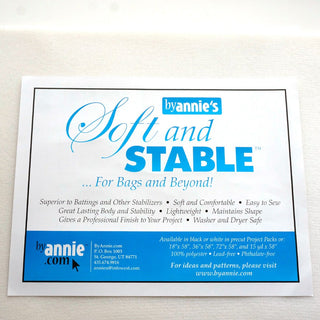

EB-FUSE INTERFACING

Find out more about our favourite interfacing for bag making!

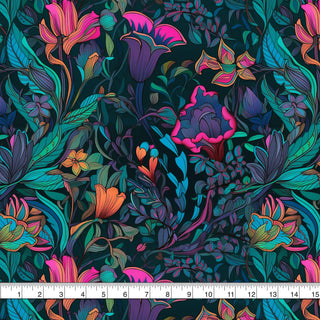

Featured Fabric collections

80's Party Printed WRC - 6.5 oz/square yard (Precut 1 Yard - 36" x 60")

$18.99

- Unit price

- /per

Printed Water Resistant Canvas - 6.5 oz/square yard (Precut 1 Yard - 36" x 60")

$17.99

- Unit price

- /per

Printed Light Weight Cotton Canvas - 7.5 oz/square yard (Precut 1 Yard)

$19.99

- Unit price

- /per

Specialty Fabric

View allTeal Ephemera // Tim Holtz Eclectic Elements - Palette - (1/4 yard)

$4.89

- Unit price

- /per

Teal Butterflies // Tim Holtz Eclectic Elements - Palette - (1/4 yard)

$4.89

- Unit price

- /per

Teal Wallpaper // Tim Holtz Eclectic Elements - Palette - (1/4 yard)

$4.89

- Unit price

- /per

Teal Tiny Print // Tim Holtz Eclectic Elements - Palette - (1/4 yard)

$4.89

- Unit price

- /per

Cotton Collection

View allup to 50% off

* While stock lasts

clearance bin!!

On sale designer fabric and quality products to be cleared. Get these products while they last.

Fast Shipping

We ship daily from Canada across North America, and globally. Choose rates at checkout that are synced directly from our shipping providers.

Quality Products

Shop our quality products and patterns, knowing they are tried and tested by 1000's of our customers.

Secure Checkout

Use our secure checkout and up to date payment processing screens with confidence. Keep your payment data private and secure!

Come Shop with us!

50 Manitoba Court

Spruce Grove, AB Canada

- Mon-Friday: 10:00 - 4:30 pm

- Saturday: 10:00 - 2:00pm

- Sunday: Closed

NOTE: We are closed on the SATURDAYS of all weeks that have a STAT holiday (long weekends).

Let customers speak for us

from 1654 reviewsI have tried other swivel hooks. None match these (and all Emmaline hardware) for quality when it comes to feeling sturdy and reliable.

I ordered 5 bag hardware items, lock, slider, rivets, label & pulls plus navy zipper tape all in rose gold. Always top quality, quick shipping and great customer service!

I totally blown away when my order arrived so quickly!! Everything was in tact and nicely packed. I had never ordered the Rex Faux Leather before but am extremely pleased I did. Quality and color were perfect for the wallet I’m making. My customer won’t need to worry about the clasp as it is great quality and will undoubtedly last thru many uses! Highly recommend all the Leather Emmaline offers. And the matching thread is perfect too! Thanks Emmaline and staff for great service and products.

I’m always happy with anything I order from Emmaline bags. Whether it is hardwear or fabric. . Meets my expectations and then some. Things arrive very !!!! Quickly. It’s my go to store

Love all Emmaline hardware,! It has a great look, installs and holds well in my projects. The colours are consistent so I can use my old with new! Thanks Emmaline, your hardware makes all projects look professional

Love all the products and the service is great next day is fabulous :-)

I have ordered many bag pieces of hardware from them and they never disappoint. Great selection and fast service. I would recommend them.

So soft snd colourful with excellent service!

Excellent quality as always from Emmaline Bags.

It’s gonna be a fun project

The new dull finish on the edge coat is great and the sandy beige colour is a good match to natural cork.

I love the love the look this webbing gives to my bags. It’s soft and the 1 1/2” width is very comfortable to wear. I’m happy you have this available in a variety of colours. The walnut & ivory pairs beautifully with the tan mora faux leather

Nice fabric Northcott is always good quality. Haven’t used it yet

Perfect for what I want to do! a knitting pouch with holes for the wool!